Production efficiency with visual scheduling

Production lead times of motion control products and systems are decreased and controlled with visual scheduling implemetation. Combined with aggressive cross-training, visual scheduling shows the whole picture to production. The entire team functions with a single purpose.

Visual systems at ORMEC coordinate:

Visual systems at ORMEC coordinate:

Build and test of products

Customer order shipments

Inventory status

Sub-assembly supermarkets

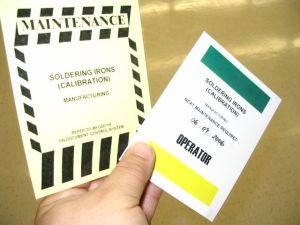

Preventative maintenance of equipment

5S methodology

Operator cross-training

Operators are quickly informed of the requirements for each work cell. Visual scheduling fosters open communication.

Current metrics are displayed and easy to understand.

Coordination of preventative maintenance, order flow and material status is visually controlled and managed by the operators.